Photo Chemical Machining for RF, Microwave & Satellite Communications Components

As RF, microwave, and satellite communications systems push further into higher frequencies, tighter tolerances, and more demanding operating environments, the limitations of conventional metal fabrication become increasingly clear. Photo chemical machining (PCM) provides engineers and designers with a proven way to manufacture ultra-precise, burr-free metal components that meet the electrical, thermal, and mechanical requirements of modern high-frequency communications.

At Conard, we partner with OEMs, contract manufacturers, and research organizations to produce function-first, production-ready precision metal components for RF and microwave devices—without tooling constraints, mechanical stress, or design compromise.

Why Photo Chemical Machining Is Ideal for RF, Microwave & Satellite Applications

High-frequency communications systems are unforgiving. Even minor dimensional deviations, edge burrs, or surface defects can degrade signal integrity, introduce noise, or cause thermal and mechanical failure.

Photo chemical machining eliminates many of the risks inherent to stamping, laser cutting, or EDM by using a chemical etching process rather than mechanical force or thermal energy.

Key advantages for RF and satellite communications include:

- Burr-free edges that preserve electrical performance

- No heat-affected zone (HAZ) to alter material properties

- Excellent feature repeatability for tight pitch geometries

- Stress-free processing that prevents warping or distortion

- Rapid design iteration without hard tooling costs

Applications of Photo Chemical Machining in RF & Microwave Systems

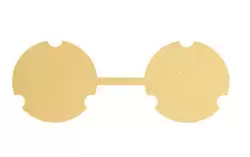

RF & Microwave Shielding Components

Electromagnetic interference (EMI) and radio frequency interference (RFI) are constant challenges in densely packed communications hardware. PCM is widely used to manufacture:

- RF shielding cans and frames

- EMI/RFI shields with fine vent patterns

- Shielding gaskets and grounding springs

- Multi-level shielding structures

Filters, Resonators & Frequency Control Components

Precision geometry is essential in RF and microwave filters, where performance depends directly on feature accuracy and edge definition. PCM is commonly used to produce:

- Bandpass and low-pass filter elements

- Microwave resonator plates

- Frequency selective surfaces (FSS)

- Etched tuning components

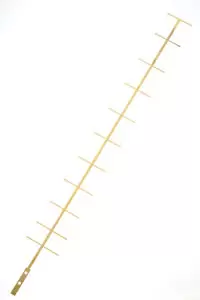

Waveguide & Antenna Components

Waveguides and antennas used in satellite communications often require thin, lightweight metal parts with intricate profiles. Photo chemical machining enables:

- Etched waveguide inserts

- Antenna arrays and elements

- Slot antennas and RF apertures

- Precision spacers and alignment shims

Satellite Communications Hardware

In satellite systems, mass reduction, reliability, and thermal stability are non-negotiable. PCM is used extensively for:

- Satellite RF enclosures and shielding

- Structural foils and brackets

- Grounding and bonding components

- Thermal and RF hybrid components

Materials Commonly Used in RF & Microwave Photo Chemical Machining

PCM supports a wide range of metals used in high-frequency communications, including:

- Copper and copper alloys

- Beryllium copper

- Nickel silver

- Stainless steel

- Aluminum alloys

- Kovar and specialty alloys

These materials can be etched with tight feature control and consistent edge quality, preserving both electrical conductivity and mechanical integrity.

Why Engineers Choose Conard for RF & Satellite PCM

Conard Corporation has over 60 years experience as a photochemical machining supplier. Our team of engineers are here to help from design consultation all the way through production.

Contact Us today to begin your RF photochemical machining project!